When it comes to tightening bolts just right, your choice of torque wrench can make all the difference. You want precision, reliability, and confidence that you’re applying the exact force needed—nothing more, nothing less.

But with so many types of torque wrenches out there, how do you know which one gives you the most accurate results? Whether you’re a professional mechanic or a DIY enthusiast, understanding which torque wrench delivers pinpoint accuracy can save you time, money, and frustration.

Stick with me as we break down the most accurate torque wrenches available and help you make the best choice for your projects.

You May Like

- [APPLICATION]: A beam style torque wrench is a must-have tool for…

- [PRECISION]: This torque wrench uses a calibrated scale fitted to the…

- [QUALITY]: This dual drive torque wrench is constructed with a powerful…

- [EASY-TO-READ]: This intuitive scale is calibrated in both directions from…

- PRECISION – Ships pre-calibrated to +/- 4% accuracy and ready to use….

- DURABLE – Reinforced ratchet gear head constructed from hardened, heat…

- LONG-LASTING – Rust & corrosion protection with our unique and newly…

- PERFORMANCE – Features an easy-to-read, highlighted yellow print dual-range…

- HIGH-PRECISION TORQUE WRENCH: With a dual measurement system, our…

- QUALITY AUTOMOTIVE WRENCH: This beam torque wrench is manufactured to high…

- VERSATILE CAR-NUT WRENCH: Our beam torque wrench is a must-have tool for…

- BIDIRECTIONAL TOOL: Designed for both left and right hands, our automotive…

- PRECISE & HIGH QUALITY – Manufactured in Taiwan, our torque wrench is…

- DURABLE – Built to last, featuring a reinforced ratchet gear head made from…

- LONGEVITY – Protect your investment with our proprietary Electro-Black…

- PERFORMANCE – Easily read and set torque levels with our patent-pending…

- 【High Precision & Easy Reading】With a dual-range scale of 20-240…

- 【 “Click” Type】The ‘Click’ Type design of torque wrench produces a…

- 【Durable Construction】The aluminum shaft of this bike torque wrench…

- 【Easy Torque Setting】To set the torque value, pull down and hold the…

Types Of Torque Wrenches

Digital torque wrenches use electronic sensors and show readings on a screen. They are usually very accurate, within about 1%. These wrenches can show small changes in torque and sometimes the angle, which helps in precise jobs. They need batteries and can cost more than other types.

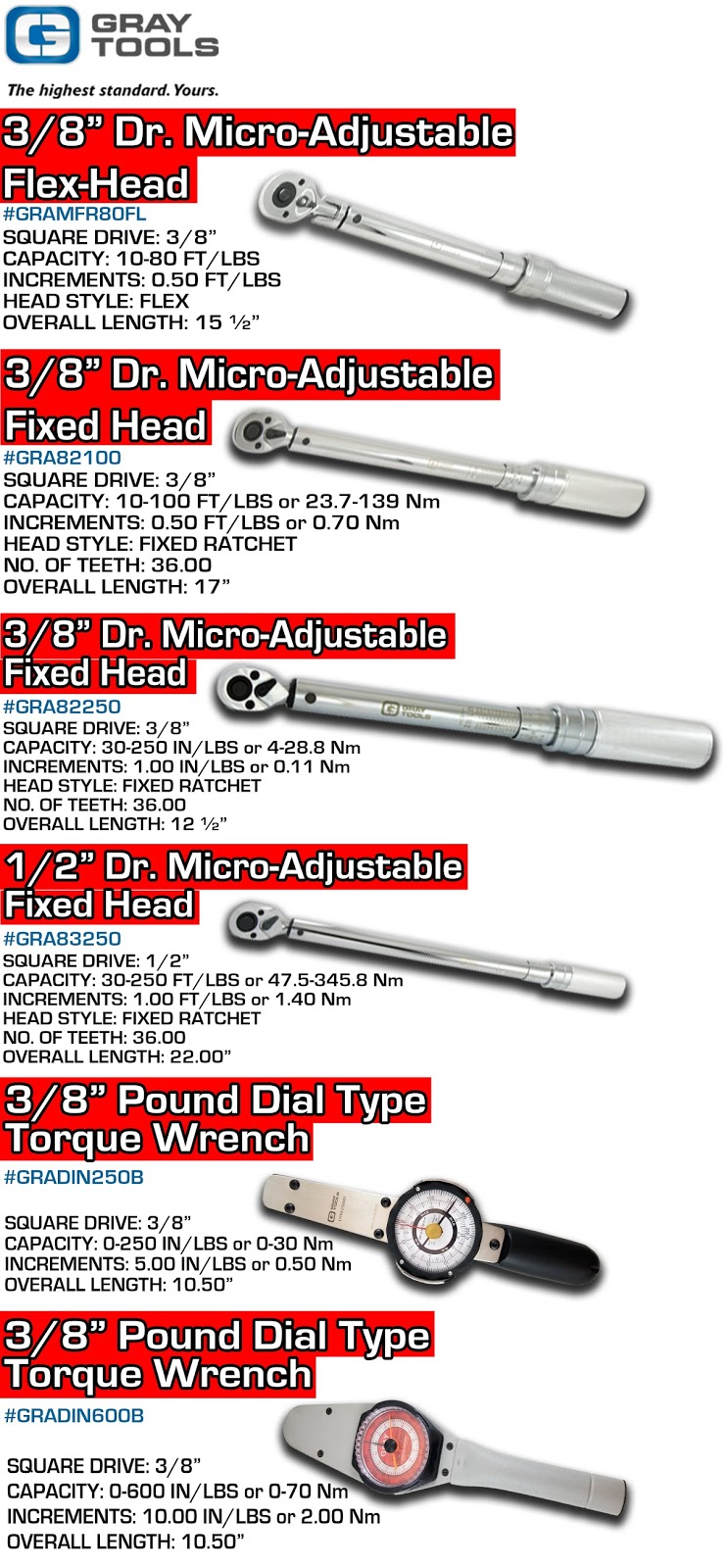

Dial torque wrenches have a dial gauge that shows the torque applied. They give clear visual feedback and are quite accurate. Users must watch the dial carefully while tightening.

Beam torque wrenches work by bending a beam. A pointer shows the torque on a scale. They are simple and reliable, but you must watch the pointer while using them.

Click torque wrenches make a clicking sound when the set torque is reached. This feature helps prevent over-tightening. They are popular but need regular calibration to stay accurate.

Pneumatic torque wrenches use air pressure for fast tightening. They are strong and good for heavy work but may be less precise than digital or dial types.

Credit: www.reddit.com

Accuracy Comparison

Digital torque wrenches use sensors and show readings on a screen. They are very precise, often within ±1%. Easy to read and measure small changes. Some show torque angle too. But they cost more and need batteries.

Dial torque wrenches have a gauge with a needle. They are also accurate but you must watch the dial closely. No batteries needed. They work well for many jobs.

Beam torque wrenches are simple and very reliable. You read the pointer on a scale. They last long but need careful reading. Often accurate enough for most tasks.

Calibration is key for all types. Without it, accuracy drops. Regular checks keep readings true.

Quality and brand affect accuracy too. High-quality wrenches hold calibration better and last longer. Cheaper tools may lose accuracy fast.

Pros And Cons Of Each Type

Digital torque wrenches offer very precise readings using electronic sensors. They show numbers clearly on a screen, making them easy to read. Some models also measure the torque angle, which helps in special tasks. These wrenches are accurate to about ±1%. The downside is they can cost more and need batteries to work.

Dial wrenches use a dial gauge to show the torque applied. They provide clear, real-time readings and are quite accurate. These tools are good for users who prefer an analog display. They do not need batteries but can be a bit harder to read at a glance compared to digital ones.

Beam wrenches are simple and durable. They show torque with a moving pointer over a scale. You must watch the pointer carefully during use, which can be tricky. These wrenches are usually accurate but less convenient for quick readings.

Click wrenches give a click sound when the set torque is reached. They are easy to use and popular for many jobs. However, they need regular calibration to keep accuracy. Over time, the click may become less precise if not maintained well.

Credit: edmfast.com

Calibration And Maintenance

Regular calibration keeps torque wrenches accurate and reliable. Over time, tools can lose precision due to use and wear. Calibration checks the tool’s settings against a known standard.

Common calibration methods include using a torque tester or sending the wrench to a professional service. Calibration ensures the wrench applies the correct force every time.

Maintaining accuracy means storing the wrench properly. Avoid dropping or exposing it to moisture. Always reset the wrench to its lowest setting after use. This helps keep the internal spring from weakening.

Regular checks and careful handling extend the life and accuracy of torque wrenches. This is especially important for click-type and digital wrenches, which rely on precise internal mechanisms.

Choosing The Right Torque Wrench

Accuracy depends on the type and quality of the torque wrench. Digital and dial torque wrenches offer precise readings, ideal for precision work. Digital wrenches use electronic sensors and show results on a screen. They are easy to read and can measure small increments, but need batteries and cost more.

Dial torque wrenches have a dial gauge to show torque. They are accurate but require careful reading. Deflecting beam wrenches are simple and durable, but you must watch the pointer closely.

| Type | Accuracy | Pros | Cons |

|---|---|---|---|

| Digital | ±1% | Easy to read, measures small increments | Needs batteries, more expensive |

| Dial | High | Clear display, no batteries needed | Requires careful reading |

| Beam | Good | Simple, durable, no calibration needed | Must watch pointer, less convenient |

Budget-friendly options usually include beam or click-type wrenches. They work well if used properly and calibrated often. For recommended brands, choose ones known for quality and reliability.

Credit: www.reddit.com

Frequently Asked Questions

What Is The 20 Rule For Torque Wrenches?

The 20% rule for torque wrenches means never use less than 20% or more than 100% of the wrench’s capacity. This prevents damage and ensures accuracy.

Which Type Of Torque Wrench Is Considered To Be The Least Accurate?

Pneumatic torque wrenches are considered the least accurate due to inconsistent air pressure and control. They lack precision compared to digital or dial types.

How Accurate Is A Click Type Torque Wrench?

A click type torque wrench typically offers ±3-5% accuracy when properly calibrated. Regular calibration ensures consistent, reliable torque application.

How To Tell If A Torque Wrench Is Accurate?

Check accuracy by comparing torque wrench readings to a calibrated tester or known torque standard. Regular calibration ensures precise measurements.

Conclusion

Digital and dial torque wrenches offer high accuracy for precise tasks. Beam-type wrenches also provide good accuracy but need careful reading. Regular calibration keeps any torque wrench reliable over time. Choose the wrench that fits your needs and budget. Proper use and maintenance ensure accurate results every time.

Accuracy matters most for safe and effective tightening.